20

2023

-

04

Chlorinated Polyvinyl Chloride(Perchloroethylene)(CPVC)

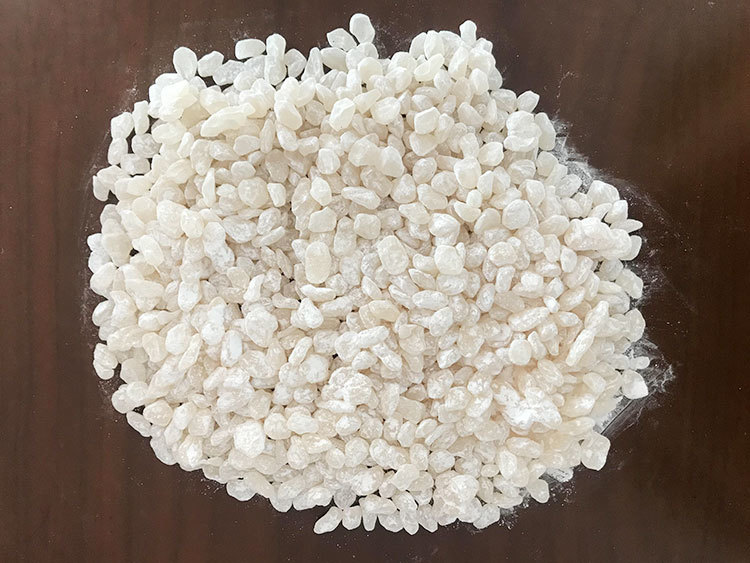

Chlorinated polyvinyl chloride (CPVC), also known as perchloroethylene, is a new synthetic polymer material produced by a specific brand of polyvinyl chloride (PVC) and chlorine gas under the action of substitution reaction, is a white or yellowish movable solid powder.

1.Characters

Chlorinated polyvinyl chloride (CPVC), also known as perchloroethylene, is a new synthetic polymer material produced by a specific brand of polyvinyl chloride (PVC) and chlorine gas under the action of substitution reaction, is a white or yellowish movable solid powder. The basic properties are similar to PVC, but the CPVC produced by chlorination modification of PVC resin, its heat resistance, physical and mechanical properties, chemical stability and flame retardant properties have been significantly improved, is a kind of high quality and cheap engineering plastics.

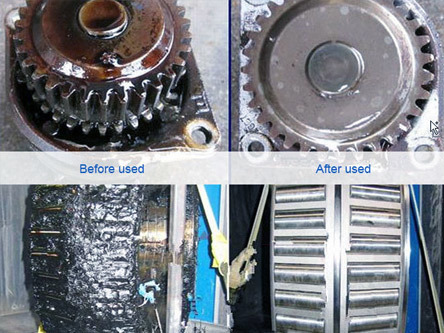

Used in coatings and adhesives, has excellent dielectric characteristics, good electrical insulation, thermoplasticity and film formation, its chemical properties is very stable, corrosion resistance, water resistance, not easy to burn, soluble in ketones, chlorinated hydrocarbons, aromatics, esters and some alcohols.

•Superior Heat Resistance

•Superior Chemical Resistance and Corrosion Resistance

•Superior Flame Retardant

•Superior Electric Insulation Properties

2.Application:

CPVC can replace traditional thermoplastic engineering plastics, widely used in petroleum, chemical industry, building materials, shipbuilding, electrical appliances, printing and dyeing, electroplating, food and paper and other fields, mainly used in the manufacture of heat and corrosion resistant pipes and accessories, residential pipe (hot water pipe) system, communication pipe system, sewage pipe system,etc. At the same time, according to the degree of chlorination, CPVC can also be used for chlorinated fiber modification, manufacturing of composite materials, foaming materials, coatings and adhesives. In addition, CPVC can also be used as a plastic modifier, and thermoplastic or thermosetting plastics mixed to manufacture alloy, improve the performance of the material, so that it becomes a more superior engineering plastics. Manufacture vinyl perchloride special paint, UPVC adhesive, vinyl perchloride fire retardant coating, leather polish and make plastic toys, etc.

|

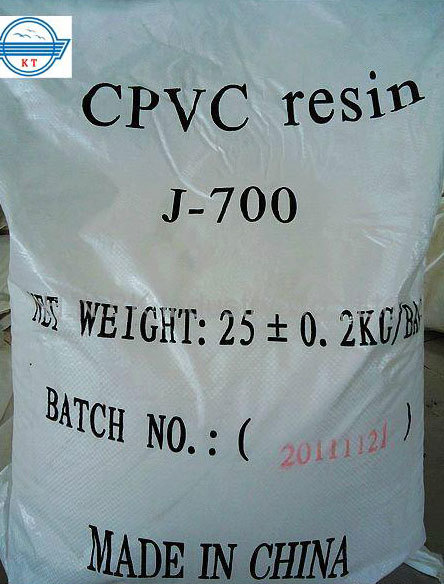

3.Packaging and storage: This product is packed with plastic woven bags lined with polyethylene film bags. Net weight of per bag is 20kg or 25kg. Stored in a dry, ventilated and cool place to prevent sun exposure and moisture. |

4.Specification:

A fine, loose grain or white powder, comply with HG2002-91 standard.

|

Grade |

J-700 |

Z-500 |

T-500A |

TN-500B |

TN-500R |

N-500 |

|

Chlorine Content % |

67±0.5 |

67±0.5 |

67±1 |

67±1 |

62±1 |

66±1 |

|

Viscosity (S) Coating -4 cups (10% xylene solution, 25℃) |

-- |

-- |

10-13 |

14-18 |

14-20 |

40-120 |

|

Ash Content %≤ |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|

Whiteness(160℃,10min)% |

75 |

75 |

-- |

-- |

-- |

-- |

|

Vicat softening temp.℃≥ |

105 |

105 |

-- |

-- |

-- |

-- |

|

Thermostability, min≥ |

30 |

30 |

20 |

20 |

20 |

20 |

|

Application |

Pipes,Plates and Sheets |

Piping Fittings, |

Paint,Coating |

Paint,Coating, Adhesives |

Paint,Coating, Adhesives |

Adhesives |

|

Above is just part of our grades, if you want to know further information or more grades, please contact us freely. |

||||||

Prev

Prev