CATEGORY

Ethylene Glycol Tertiary Butyl Ether (ETB)

Tel:

Frank:

Ethylene Glycol Tertiary Butyl Ether (ETB)

1.Introduction:

Product Name: Ethylene Glycol Tertiary Butyl Ether

CAS No.: 7580-85-0

Molecular Formula: C6H14O2

Molecular Weifght: 118.18

2.Character:

It is colorless transparent with mint fragrance scent flammable liquid, can be miscible with most organic solvents, can be soluble with amino, nitro, alkyd, acrylic and other resins. At room temperature (25℃), can be miscible with water. It is low toxicity, low irritation.

Performance | Parameter | Performance | Parameter |

Density Ratio(water=1) | 0.903 | Initial Boiling Point | 150.5℃ |

Freezing Point | <-120℃ | 5% Distillate | 151.0℃ |

Ignition Point (Closed) | 55℃ | 10% Distillate | 151.5℃ |

Ignition Temperature | 417℃ | 50% Distillate | 152.0℃ |

Surface Tension(20℃) | 2.63Pa | 95% Distillate | 152.0℃ |

Vapour Pressure(20℃) | 213.3Pa | Quantity of Distillate(Vol) | 99.9% |

Solubility Parameter | 9.35 | Thousand Points | 152.5℃ |

3.Application:

Ethylene glycol tertiary butyl ether is the main alternative to ethylene glycol butyl ether. In contrast, it has the advantages of low odor, low toxicity, low photochemistry, mild irritation to skin, good water compatibility, good dispersion stability for latex coatings, soluble with most resins and organic solvents, and good hydrophilicity. The water-dispersed coating made with this solvent has good storage stability, especially in winter under low temperature conditions.

It can be widely used in paint, ink, cleaning agent, fiber wetting agent, plasticizer, Organic synthesis intermediates, paint remover and many other fields.Its main uses are as follows:

3.1 Water-based Coating Solvent

It is mainly used for water-based system solvent, latex water-dispersed coating in coating industry. Because the HLB value of ETB is close to 9.0, its function in the dispersion system plays the roles of dispersing agent, emulsifier, rheological agent and co-solvent. It has good performance for latex paint, colloidal disperse coating and dissolved aqueous solution resin coating in water-based coatings, and it is used for interior and exterior coatings of buildings, automotive primer, color tinplate and other fields.

3.2 Paint Solvent

3.2.1 As a dispersant. When producing extra black amino paint and extra black acrylic paint, it usually takes a lot of time to grind high pigment carbon black to reach a certain fineness. However, the grinding time of high pigment carbon black soaked by ETB can be shortened by more than half, and the paint appearance after finishing is more flat and smooth.

3.2.2 As leveling agent and defoamer, improve the drying speed, flatness, gloss, adhesion fastness of water dispersed coatings. Because of its tert-butyl structure, it has high photochemical stability and security, and can eliminate pinholes, small particles and bubbles. Water dispersion coating made from ETB has good storage stability, especially in winter under low temperature conditions.

3.2.3 Improve the gloss. ETB applied in amino paint, nitro paint, can prevent the production from "orange peel" like markings, the paint film gloss can increase 2% ~ 6%.

3.3 Ink Dispersant

The ink made of ETB as solvent, or as a diluent dispersant used in printing ink, can greatly improve the rheological property of ink, improve the quality of high-speed printing and gloss, adhesion.

3.4 Fibre Extractant

American Alied-Signal company extracted polyethylene fiber containing 76% mineral oil with ETB, after extraction, the content of mineral oil in fiber reduced by 0.15%.

3.5 Titanium oxide phthalocyanine dye

Japan Canon company added Ti (OBu) 4 into the ETB solution of 1, 3-diamino-isodihydroindole and stirred it at 130℃ for 3h to produce an 87% purity titanium oxide phthalocyanine dye. The crystalline titanium oxide phthalocyanine made of porous titanium oxide phthalocyanine and ETB can be used as photographic photosensor, which has high sensitivity to long wave light.

3.6 High efficiency household cleaner

Japan's Asahi Denko Company uses propylene oxide and KOH containing ETB to produce polyoxypropane mono-butyl ether, which is an ideal efficient household cleaner.

3.7 Corrosion resistant hydrosol paint

Japanese paint company with dimethyl ether, acrylic resin, ETB, butanol, TiO2, cyclohexylamine carbonate, defoamer made a spray corrosion resistant hydrosol paint.

3.8 Radio element carbon film resistor

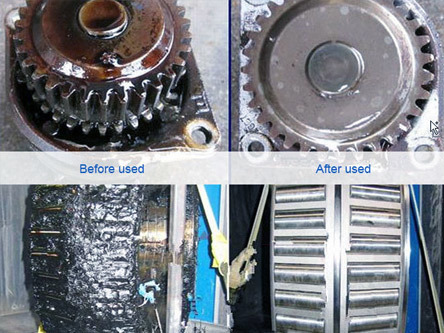

Carbon film resistance that using ETB as resistance liquid,which surface is smooth and flat, can eliminate the bad phenomenon of pinhole and thick edge, improve the performance of electrical components.

3.9 Fuel additive

ETB can be used as a co-solvent and modifier of new boiler fuel, which not only improves combustion efficiency, but also reduces emissions. As a new energy source for boilers and large Marine diesel engines, ETB has advantages in terms of rigid demand for environmental protection and policy dividends.

| 4.Packaging and storage: Packaging is 180KG/Iron drum. Store in a cool, ventilated warehouse. Keep away from fire and heat source. The packaging should be sealed and not in contact with air. It should be stored separately from oxidants, acids and alkaline. Avoid mixed storage. Do not store in large quantities or for long time. Explosion-proof lighting and ventilation facilities shall be adopted. Mechanical equipment and tools that are easy to produce sparks shall be prohibited. The storage area shall be equipped with leak emergency treatment equipment and suitable holding materials. |

CONSULT ONLINE

RELATED PRODUCTS