20

2023

-

04

High Chlorinated Polyethylene (HCPE)

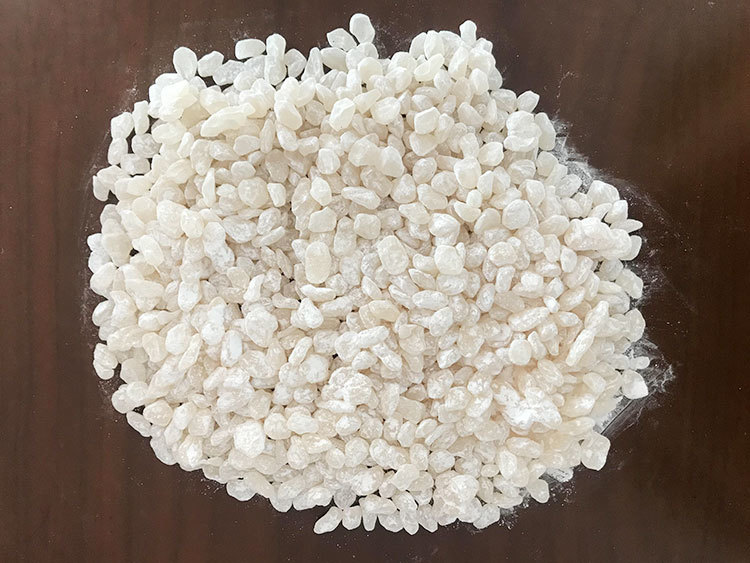

High chlorinated polyethylene is a polymer with excellent comprehensive properties, soluble in aromatics, esters, ethylene glycol, etc., and has a good compatibility with all inorganic pigments and organic pigments. It has good film forming property, weather resistance, ozone resistance, flame retardant, oil resistance and chemical resistance, in many fields to replace epoxy resin, chlorinated rubber, chlorosulfonated polyethylene, perchloroethylene and other materials.

1.Characters:

High chlorinated polyethylene is a polymer with excellent comprehensive properties, soluble in aromatics, esters, ethylene glycol, etc., and has a good compatibility with all inorganic pigments and organic pigments. It has good film forming property, weather resistance, ozone resistance, flame retardant, oil resistance and chemical resistance, in many fields to replace epoxy resin, chlorinated rubber, chlorosulfonated polyethylene, perchloroethylene and other materials.

2.Application:

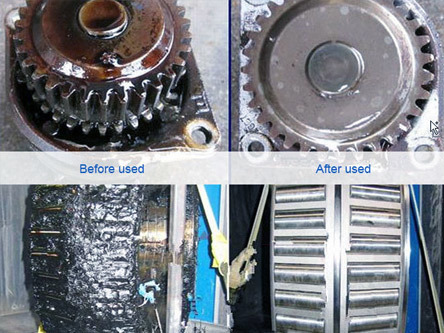

High chlorinated polyethylene is mainly used in the manufacture of flame retardant, wear-resistant heavy anticorrosive coatings, high-grade adhesives, advanced inks. In the aspect of coatings, can be widely used in chemical equipment, oil pipeline, marine facilities, metallurgical mines, salt, fishing, three waste treatment, power equipment, container and other industries.

Applications in other fields: can be used as adhesives of paper, fiber fireproof agent (flame retardant), neoprene rubber, nitrile rubber and other rubber series and heat resistant modifier, as well as ink modifier for paper, aluminum foil, etc.

|

3.Packaging and storage: Packaging is 20KG/bag. It should be stored at room temperature and dry. This product belongs to non-dangerous goods and has stable chemical properties. |

4.Specification:

|

Grade |

HCPE-10L |

HCPE-30M |

HCPE-40H |

HCPE-65H |

HCPE-100H |

|

Appearance |

White Powder |

White Powder |

White Powder |

White Powder |

White Powder |

|

Chloride Content(%) |

67±1 |

67±1 |

67±1 |

67±1 |

67±1 |

|

Viscosity, 25℃mPa.s,20% in xylene |

10-20 |

20-35 |

-- |

-- |

-- |

|

Viscosity, 25℃ mPa.s,10% in |

-- |

-- |

30-50 |

60-75 |

90-110 |

|

Application |

Paints, Coatings,Inks |

Paints, Coatings,Inks |

Adhesives |

Adhesives |

Adhesives |

|

Thermal Decomposition Temperature(℃) ≥ |

110 |

||||

|

Volatility(%)≤ |

0.5 |

||||

|

Ash Content(%) ≤ |

0.4 |

||||