CATEGORY

Chlorinated Polyethylene (CPE)

Keywords:

Category:

Tel:

Selena:

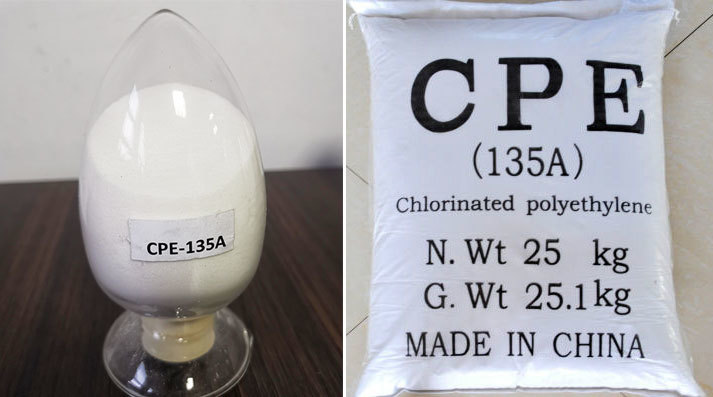

Chlorinated Polyethylene (CPE)

Characters

CPE is polymer composite material made of high density polyethylene HDPE by chlorination, it is a kind of thermoplastic elastomer, appearance is white powder. CPE has excellent flexibility, heat resistance, weather resistance, oil resistance, flame retardant, chemical resistance, ozone resistance, etc.

CPE is divided into two series based on different final applications. CPE Resin series is designed for plastic impact modification, and CPE Rubber series is for rubber application.

CPE Resin series:

|

CPE RESIN is one of the most important impact modifiers for the universal plastics market. Proper amount of CPE RESIN added into formulations of PVC, PE or PP plastic products will not only greatly enhance impact resistance but will largely improve low temperature performances, weatherability, welding strength and other performances. All in all, CPE RESIN helps fabricators and compounders meet increasing critically performance requirements and control costs. |

Properties :

◎ Superior flexibility and good low temperature impact strength

◎ Compatible with acrylic impact modifier

◎ Superior compatibility with polymers like PVC, PE and ABS

◎ Superior weatherability

◎ Superior Processibility

◎ Excellent corner strength

◎ High surface gloss

◎ Good filler acceptance

◎ Cost effective system

|

Application of CPE Resin series: 1). Impact modifier for rigid and semi-flexible products 2). Application in Flame Retardant ABS Addition of certain percentage of CPE RESIN into flame retardant ABS formulation will not only avoid using of big amount of inorganic flame retardants in the formulation, which causes physical performance lost, but will play positive role in enhancing the flame retardancy of the whole system and substantially improve the impact strength of the end product. 3). Application in soft products As a good elastomer, CPE RESIN can be used directly for soft products. The soft products produced have superior weatherability and long service life. |

CPE Rubber series:

Characteristics:

◎ Excellent chemical, heat, and ignition resistance

◎ Performance over a broad temperature range

◎ Outstanding heat-aging characteristics

◎ Unique crumb form, permitting easy blending, formulating, and processing

◎ Polymer shelf stability measured in years

◎ Good processability on equipment common to the rubber industry

◎ Attractive economics

|

Application of CPE Rubber series:

1). Automobile Hoses and Industrial Hoses.

|

Packaging and Storage:

Net weight is 25kg per bag. Store at room temperature and dry. This product belongs to non-dangerous goods and has stable chemical properties.

Specification:

|

Index |

Request |

|||||

|

CM135A |

CM130B |

CM135B |

CM140B |

CM235C |

CM240C |

|

|

Chlorinity% |

35±1 |

30±1 |

35±1 |

40±1 |

35±1 |

40±1 |

|

Melting enthalpy J/g≤ |

65 |

65 |

60 |

60 |

70 |

70 |

|

Shore hardness Shore A ≤ |

65 |

65 |

60 |

60 |

70 |

70 |

|

Tensile strength Mpa≥ |

8 |

8 |

7 |

7 |

7 |

7 |

|

Elongation at break %≥ |

700 |

700 |

600 |

600 |

600 |

600 |

|

Mooney viscosity ML(1+4)125℃ |

65±5 |

55±5 |

65±5 |

70±5 |

60±5 |

65±5 |

|

Volatile Matter %≤ |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

No. Of colored particles 个/200g ≤ |

30 |

30 |

30 |

30 |

30 |

30 |

|

Thermal Decoposition Temperature ℃≥ |

130 |

130 |

130 |

130 |

130 |

130 |

|

Apparent Density g/ml≥ |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

0.40 |

CONSULT ONLINE

RELATED PRODUCTS